Activated carbon is a substance produced industrially from organic raw materials (most often from wood, less often from peat and animal bones). Let's take a closer look at how activated carbon is produced.

How coal is activated in industry

First, the raw material, which will subsequently become activated carbon, undergoes a carbonization reaction. This process involves firing at high temperatures in an inert atmosphere and in the absence of oxygen. But the carbonate obtained after this does not yet have the beneficial properties of activated carbon, since the number of pores in it is still small. Such raw materials also undergo an activation process.

When activating coal in industrial conditions, mainly hard or brown coal, wood or coconut shells are used.

Carbon activation process

Burnt carbonate or coal can be treated with special compounds of chemical origin or hot water steam.

How is activated carbon activated? Steam is used to activate the carbon. Let's take a closer look at this process.

- In a controlled environment, the carbonate is treated with water at high pressure and temperatures ranging from 800 to 1000 °C. During this treatment, a chemical reaction occurs on the surface of the coal and previously closed carbon pores open. Thus, the area of the internal surface of coal increases many times - up to 1.5 thousand square meters. m per 1 gram of coal. By adjusting the conditions, different adsorption capacities of coal can be achieved.

- The primary material is first impregnated with chemicals - a solution of potassium carbonate or zinc chloride.

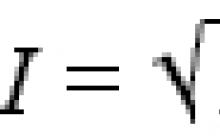

During the steam activation process, the following reaction occurs:

- C + H 2 O → CO + H 2

And with an excess of water molecules, the following process can occur:

- C + 2H 2 O → CO 2 + 2H 2

Coal can be activated not only in a vacuum, but also with limited access to oxygen. In this case, some part of the carbon burns, creating the necessary temperature for activation, but the amount of activated carbon at the output in this case is significantly reduced.

As a result of activation carried out by thermochemical method, carbon with coarse pores is obtained, which is used only for decolorizing liquids. And activated carbon obtained by steam activation is suitable for cleaning.

Coal finishing

After the main processing, the coal is cooled, and then sifted and sorted. Sludge (dust waste) is sifted out, after which the coal is further processed as carefully as required to obtain the final result. It can be impregnated with various chemical compounds (impregnation process), washed with acids, then dried and crushed. Then the activated carbon is packaged in appropriate industrial containers.

With the help of water activation, it is possible to increase the internal area of \u200b\u200bthe coal. This makes activated carbon an excellent sorbent (a substance that selectively absorbs gases or dissolved substances from the environment). But not the entire treated surface can be adsorbed. The pores are too small for the adsorption (absorption of a substance by the surface layer of a solid) of large molecules. At the same time, it is possible to increase the size of the pores if the activation of coal is not of plant origin, but of animal origin.

How to make activated carbon at home, you need to understand - what is it actually needed for?

There are probably charcoal tablets in every first aid kit, but then why make it yourself?

A large amount of coal will be needed for those who have filters for.

The contents of their cartridges can be cheaply and simply replaced with a self-made absorbent.

The most versatile raw material for producing an activated absorbent is wood, preferably with a low resin content. Often, birch is used for dry distillation of wood, which is how the process of producing coal can be called. But other hardwoods can also be used.

Sometimes coconut shells are used to produce carbon absorbent. Naturally, after the coconut itself is rid of water and nutritious pulp.

By the way, coal from this exotic raw material has many micropores (up to 2 nm). The surface of wood is covered with mesopores (up to 50 nm) and macropores (over 50 nm). All these indicators determine what size of pollution particles the absorbent will absorb.

For the industrial production of activated carbon, animal bone material is used, by the way. It is from burnt animal bones that those black pills from the pharmacy are made.

Dry distillation of raw materials

This is the first step that needs to be carried out before preparing activated carbon at home.

To do this, you will first need a source of open fire.

For these purposes, you can use a fire, a blowtorch, a gas stove, or an oven.

Wood, or coconut shells, need to be crushed into small pieces.

The boards need to be dry, without bark and knots.

It is better not to use young wood - the optimal age of the tree used is 50 years.

After this, the wood material is placed in a container with a tight-fitting lid. A tin can, the contents of which have already been used for their intended purpose, is best suited. In its bottom you need to make several holes not exceeding the size of wooden planks.

After this, the vessel must be placed on the fire with the holes facing down. With the lid tightly closed, gases and smoke will burn in the flame - smoke and burning smell will be minimal. That is, if you have a good hood, this operation can be carried out in the kitchen - on a gas stove.

If there is no container with a lid, then dry sifted sand will help out. They will need to fill the bars completely - this way they will char evenly, without access to air.

Thanks to this, its absorption properties are improved - it better absorbs mineral and mechanical impurities.

That is why activated carbon is used in various types of filters: to purify liquids and air mixtures from various impurities.

There are several ways to activate a carbon absorbent.

And in order to know how to make activated carbon at home from coal, you need to know how to activate it.

Most often, it is enough to hold the charred pieces, wrapped in cheesecloth or cloth, over a source of steam. You can, for example, use dishes for steaming food, or a kettle.

An effective way to activate is boiling in clean water. It has only one drawback: the boiling water washes out coal soot from the surface of the coals, which significantly reduces the absorption area. You need to boil for 20-25 minutes.

For another method of opening the pores of coal, you will need a regular kitchen utensil. It will be needed to prepare a 25% aqueous solution. It is in this salt mixture that the coal is placed for a day. After 24 hours, you need to remove the pieces of absorbent and rinse them under running clean water. As a result, there should be no salt left on the already activated carbon.

As you can see, all activation methods are based on contact of the reagent with water. Therefore, for further use of activated carbon, it must be dried.

Drying

You can dry it in different ways:

- in the sun, placed on a flat plastic or metal tray

- in a container used for distillation, over an open fire

- in a warm room, on a metal or plastic tray

- in the oven - on a tray

Everyone determines for himself the time during which he wants to get dried.

Storage

Dried activated carbon is usually stored in a cool, dark place. It can be crushed first, but storing whole pieces is also allowed.

For storage, use a glass container with a tightly sealed lid. When coal is exposed to air for a long time, it loses its unique absorption properties after just a few months. If you do not violate the storage conditions listed above, then coal can be stored much longer.

However, no one forbids immediately using the entire supply of dried carbon absorbent: to fill air and water filters, to make a homemade gas mask box.

Thus, you can easily see how simple and cheap it is to produce even a significant amount of activated carbon for your personal needs. This will significantly reduce the cost of operating kitchen hoods and cleaning systems. And the user will quietly gain unique knowledge in physics and chemistry.

How to make activated carbon with your own hands - on video:

Activated carbon, sometimes called carbolene, is used to purify dirty water or polluted air. In emergency situations, activated carbon is used to remove dangerous toxins and poisons from the body. Before preparing activated carbon, you need to make charcoal at home by burning wood or fibrous plant material. After this, activating chemicals such as calcium chloride or lemon juice can be added to complete the process.

Steps

Part 1

How to cook charcoal- When working with fire, take safety precautions and always keep a fire extinguisher handy.

-

Place small hardwood chips in a metal pot. If you don't have suitable wood, you can substitute any dense fibrous plant-based material such as coconut shells. Place the wood or plant material in a metal cauldron and cover it with a lid.

Heat the pot over an open fire for 3-5 hours to create charcoal. Place the covered pot on the fire. During cooking, you will see smoke and gas escaping through the holes in the lid. All unnecessary substances are removed along with the smoke, and only clean coal remains in the boiler.

Rinse the cooled charcoal with water. The coal in the pot remains hot for some time. Let it cool for some time. When the charcoal is cool to the touch, transfer it to a clean container and rinse it in cool water to remove any ash or other debris. Then drain all the water.

Crush the coal. Place the washed charcoal in a mortar and pestle until it becomes a fine powder. You can also place it in a heavy-duty plastic bag and grind it into a powder using a wooden chopstick or large mallet.

Wait until the charcoal powder is completely dry. If you used the plastic bag method, pour the powder into a clean bowl. Otherwise, leave it in the mortar. After about a day, the powder will dry completely.

Mix the calcium chloride solution with wood powder. Place the dry wood powder into a glass or stainless steel bowl. Add calcium chloride solution (lemon juice or bleach) to the powder in small portions, stirring constantly with a spoon.

Cover the bowl and wait 24 hours. Cover the bowl and let the mixture sit. After this, drain as much liquid as possible from the bowl. At this point the charcoal will still be moist but not wet.

Activation of the carbon will take another 3 hours. Transfer the coal back to the metal pot (cleaned) and place on the fire. The fire must be intense enough to bring the water needed to activate the charcoal to a boil. After 3 hours of boiling at the same temperature, the activated carbon will be ready.

Light a small fire in a safe place. The easiest way to make charcoal is to start a fire outside, but you can also do this in your home fireplace (if you have one). The fire must be intense enough to burn all the wood.

Part 3

How to use activated carbonClean the air in your home. Wrap a small amount of activated carbon in a piece of sheet and place it in the desired location. If you don't have a sheet, use a thick, breathable fabric such as cotton.

Build a charcoal water filter using a sock. Store-bought water filters are usually quite expensive, but you can build your own filter and get the same results using a cheaper method. Take a clean sock that doesn't smell like laundry detergent or bleach and put activated charcoal in it. Now you can purify the water by filtering it through a sock.

Prepare a clay face mask with activated charcoal. Take a small bowl and add 30 milligrams of bentonite clay, 2.5 milligrams of activated charcoal, 15 milligrams of turmeric, 30 milliliters of apple cider vinegar and 5 milliliters of honey. Then start adding water to the mixture little by little until you get a smooth paste.

Relieve bloating and gas with activated charcoal. Add 500 milligrams of powdered activated carbon to 350 milliliters of water. Drink this mixture before eating foods that cause bloating or to combat symptoms when you experience excess gas in your intestines.

Activated carbon has a long history and a wide range of applications.

Many people are interested in two questions: what is activated carbon and what is it for?? This product is a drug that helps cleanse the body. Activated carbon has been known to man for more than three thousand years. Even the inhabitants of Ancient Rome used this product to purify water and wine. Hippocrates recommended using it to cleanse the human body. A large number of recipes from that time for the preparation of activated carbon for the treatment of various diseases and poisonings have survived to this day. In the history of medicine, there are cases when this drug saved people from severe poisoning. It turns out that even several thousand years ago people knew what is activated carbon for?.

Properties of activated carbon

The properties of activated carbon are simply amazing in their versatility. Firstly, this remedy relieves the human body of intoxication caused not only by food, but also by poisons. Secondly, it is used for heaviness in the stomach and digestive problems. Thirdly, this drug helps the body cleanse itself of toxins and other harmful substances that enter the body with food. Fourthly, activated carbon is excellent. Fifthly, this drug helps get rid of allergies, dermatitis, psoriasis and swelling. Sixthly, activated carbon is used to treat various joint diseases, in particular gout. Seventh, activated carbon is a good adsorbent that relieves hangovers. Eighth, the drug can cure otitis of the middle and external ear. Ninth, this remedy is used in the treatment of epilepsy. And finally tenth property of activated carbon– getting rid of impotence.

The properties of activated carbon are simply amazing in their versatility. Firstly, this remedy relieves the human body of intoxication caused not only by food, but also by poisons. Secondly, it is used for heaviness in the stomach and digestive problems. Thirdly, this drug helps the body cleanse itself of toxins and other harmful substances that enter the body with food. Fourthly, activated carbon is excellent. Fifthly, this drug helps get rid of allergies, dermatitis, psoriasis and swelling. Sixthly, activated carbon is used to treat various joint diseases, in particular gout. Seventh, activated carbon is a good adsorbent that relieves hangovers. Eighth, the drug can cure otitis of the middle and external ear. Ninth, this remedy is used in the treatment of epilepsy. And finally tenth property of activated carbon– getting rid of impotence.

Interesting on the web:

Activated carbon. Compound

Activated carbon has the following composition: finely porous amorphous carbon, activated by special treatment. This component has adsorbent and catholic properties. The porosity of coal by volume ranges from 15 to 97.5%. Thus, The composition of activated carbon is quite simple.

Activated carbon. What are they made of?

As noted earlier, Activated carbon has been very popular for many years. What is this drug made from?? In its production, charcoal and stone coals, as well as peat, are used. The components are heated in special vacuum containers and then subjected to special processing. Now you know, What is activated carbon made from?.

Activated carbon. How to use?

Activated carbon is well known to everyone, but not everyone knows how to use it correctly. Domestic doctors recommend use activated carbon orally a few hours before meals. The average daily dosage can range from 100 to 200 milligrams per kilogram. The daily dose is divided into three doses. The duration of treatment should be from 3 to 14 days. After two weeks, the course of treatment can be repeated again.

>how to make activated carbon

What is activated carbon?

First of all, you need to figure out what activated carbon is?

Activated carbon is a porous substance, an absorbent, obtained from various carbon-containing materials of organic origin, that is, charcoal, walnut shells, hazelnut shells, coconut shells, coal coke, petroleum coke. We are, of course, interested in the simplest, most affordable and clean product. Therefore, further we will talk only about activated carbon, which can be obtained from wood.

What is activated carbon used for?

Activated carbon is used in medicine and manufacturing. In medicine it is used for various intestinal disorders, helps to cope with many types of poisoning or at least significantly reduce the harmful effects of toxins on the body (including alcohol, chemicals and radioactive ones).

In production, activated carbon is used in treatment systems. Most of all air filters for gas masks and protective masks are made using activated carbon. Industrial and home filters for water purification are also made with activated carbon.

Activated carbon at home

Making activated carbon yourself is quite simple, but for internal use, this is certainly not the best idea, since carbon can be bought at every pharmacy. But to make coal, for example, for filtering water, or in the absence of industrial designs, to make a filter for a gas mask yourself, this knowledge can be useful. Moreover, the prices for coal in the pharmacy are not low and making a large water filter from “pharmacy” coal will be expensive.

It doesn’t matter what you use (cans, barrels, pots, pans, a gas burner or a fire), the principle of making activated carbon at home or on the go is the same. It consists of three stages: the first is the production of coal, the second is its “activation” and finally drying.

So, let's start making activated carbon.

First stage:

Take a container, for example a wide tin can. The jar must be tightly closed with something. It is desirable that the jar be flat, that is, its width (diameter) should be greater than its height. You need to make several small holes of 1-2 mm in the bottom of the jar. Next, put small dry wooden chocks in a jar, close the lid tightly and put on fire. Wooden chocks are best made from wood that does not contain a large amount of resin; birch is good for this, but spruce and pine will produce a lot of smoke and there is a high probability of the resin igniting inside the can, then the process of manufacturing activated carbon will be ruined.

This stage can be called dry distillation of wood. In this case, all flammable gases (provided the lid is tightly closed) will escape into the holes made in the bottom of the jar and immediately burn in the fire. This way there will be virtually no smoke or odor, which means this method can literally be used to make activated carbon at home. But if instead of holes in the bottom you use the absence of a lid or distill wood in a saucepan or frying pan, there will be a lot of smoke, so you can only make charcoal in the open air. Using the “without a lid” method, it is better to sprinkle the lumps with dry sand so that the distillation proceeds evenly and the wood does not ignite.

Next, when the release of gases and steam stops, remove the jar from the heat and allow to cool. We open the lid and see black carbon there, but it is not yet activated carbon.

Let's move on to the second stage.

We take the coal out of the can and pour it into a pan or another can and completely fill it with water. Place on fire and boil for 20-30 minutes. This is the activation process, boiling water washes the pores of the charcoal, washing away all the minerals.

Third final stage.

We put the still damp, but already activated carbon again into a jar with holes in the bottom and put it on fire. We dry the coals in this way, now instead of flammable gas, pure water vapor comes out of the pores. After all the moisture has evaporated and the coals have cooled, the entire action can be considered complete. Activated carbon is ready! By weight, such coals feel almost weightless, because all the pores are free.

Activated carbon should be stored in a glass jar with a lid or in a sealed plastic container, so the activity of the carbon will remain for several years. But with access to oxygen, the properties of coal are lost within a few months.

"pros" and "cons" of democracy

Surveyor. Who is a surveyor? Description of the profession. Profession surveyor Surveyor training

Magellanic clouds: who are they?

Pepper Steak Sauce Creamy Pepper Sauce

How to create a competent portfolio for a designer