According to statistics, only one flight out of 8 million ends in an accident with loss of life. Even if you boarded a random flight every day, it would take you 21,000 years to die in a plane crash. According to statistics, walking is many times more dangerous than flying. And all this is largely due to the amazing reliability of modern aircraft engines.

On October 30, 2015, testing of the newest Russian aircraft engine PD-14 began on the Il-76LL flying laboratory. This is an event of exceptional importance. 10 interesting facts about turbojet engines in general and the PD-14 in particular will help you appreciate its significance.

A miracle of technology

But a turbojet engine is an extremely complex device. Its turbine operates in the most difficult conditions. Its most important element is the blade, with the help of which the kinetic energy of the gas flow is converted into mechanical rotational energy. One blade, and there are about 70 of them in each stage of an aircraft turbine, develops a power equal to the power of a Formula 1 car engine, and at a rotation speed of about 12 thousand revolutions per minute, a centrifugal force equal to 18 tons acts on it, which is equal to load on the suspension of a double-decker London bus.

But that's not all. The temperature of the gas with which the blade comes into contact is almost half the temperature on the surface of the Sun. This value is 200 °C higher than the melting point of the metal from which the blade is made. Imagine this problem: you need to prevent an ice cube from melting in an oven heated to 200 °C. Designers manage to solve the problem of cooling the blade using internal air channels and special coatings. It is not surprising that one spatula costs eight times more than silver. To create just this small part that fits in the palm of your hand, it is necessary to develop more than a dozen complex technologies. And each of these technologies is protected as the most important state secret.

TRD technologies are more important than atomic secrets

In addition to domestic companies, only US companies (Pratt & Whitney, General Electric, Honeywell), England (Rolls-Royce) and France (Snecma) possess technologies for the full cycle of creating modern turbojet engines. That is, there are fewer countries producing modern aviation turbojet engines than countries that have nuclear weapons or launch satellites into space. China's decades-long efforts, for example, have so far failed to achieve success in this area. The Chinese quickly copied and equipped the Russian Su-27 fighter with their own systems, releasing it under the designation J-11. However, they were never able to copy its AL-31F engine, so China is still forced to purchase this no longer the most modern turbojet engine from Russia.

PD-14 - the first domestic aircraft engine of the 5th generation

Progress in aircraft engine manufacturing is characterized by several parameters, but one of the main ones is the temperature of the gas in front of the turbine. The transition to each new generation of turbojet engines, and there are five of them in total, was characterized by an increase in this temperature by 100-200 degrees. Thus, the gas temperature of the 1st generation turbojet engines, which appeared in the late 1940s, did not exceed 1150 °K, in the 2nd generation (1950s) this figure increased to 1250 °K, in the 3rd generation (1960s) this parameter rose to 1450 °K; for engines of the 4th generation (1970-1980) the gas temperature reached 1650 °K. Turbine blades of 5th generation engines, the first examples of which appeared in the West in the mid-90s, operate at a temperature of 1900 °K. Currently, only 15% of engines in use worldwide are of the 5th generation.

An increase in gas temperature, as well as new design schemes, primarily double-circuit, have made it possible to achieve impressive progress over the 70 years of development of turbojet engines. For example, the ratio of engine thrust to its weight increased during this time by 5 times and for modern models reached 10. The degree of air compression in the compressor increased 10 times: from 5 to 50, while the number of compressor stages decreased by half - on average from 20 to 10. The specific fuel consumption of modern turbojet engines has been halved compared to 1st generation engines. Every 15 years, the volume of passenger traffic in the world doubles while the total fuel consumption of the world's aircraft fleet remains almost constant.

Currently, Russia produces the only 4th generation civil aircraft engine - the PS-90. If we compare the PD-14 with it, then the two engines have similar weights (2950 kg for the basic version PS-90A and 2870 kg for the PD-14), dimensions (fan diameter for both is 1.9 m), compression ratio (35.5 and 41) and take-off thrust (16 and 14 tf).

At the same time, the high-pressure compressor PD-14 consists of 8 stages, and PS-90 - of 13 with a lower total compression ratio. The bypass ratio of the PD-14 is twice as high (4.5 for the PS-90 and 8.5 for the PD-14) with the same fan diameter. As a result, the specific fuel consumption in cruising flight for the PD-14 will drop, according to preliminary estimates, by 15% compared to existing engines: to 0.53-0.54 kg/(kgf h) versus 0.595 kg/(kgf h) ) at PS-90.

PD-14 is the first aircraft engine created in Russia after the collapse of the USSR

When Vladimir Putin congratulated Russian specialists on the start of testing the PD-14, he said that the last time such an event occurred in our country was 29 years ago. Most likely, this meant December 26, 1986, when the first flight of the Il-76LL took place under the PS-90A test program.

The Soviet Union was a great aviation power. In the 1980s, eight powerful aircraft engine design bureaus operated in the USSR. Often firms competed with each other, since there was a practice of giving the same task to two design bureaus. Alas, times have changed. After the collapse of the 1990s, all industry forces had to be brought together to implement the project of creating a modern engine. Actually, the formation in 2008 of the United Engine Corporation (UEC), with many of whose enterprises VTB Bank actively cooperates, was aimed at creating an organization capable of not only preserving the country’s competencies in gas turbine construction, but also competing with the world’s leading companies.

The lead contractor for the PD-14 project is the Aviadvigatel Design Bureau (Perm), which, by the way, also developed the PS-90. Serial production is organized at the Perm Motor Plant, but parts and components will be manufactured throughout the country. The cooperation involves the Ufa Engine Production Association (UMPO), NPO Saturn (Rybinsk), NPCG Salyut (Moscow), Metalist-Samara and many others.

PD-14 - engine for long-haul aircraft of the 21st century

One of the most successful projects in the field of civil aviation of the USSR was the Tu-154 medium-range aircraft. Produced in a quantity of 1,026 units, it formed the basis of Aeroflot's fleet for many years. Alas, time passes, and this hard worker no longer meets modern requirements either in terms of efficiency or ecology (noise and harmful emissions). The main weakness of the Tu-154 is the 3rd generation D-30KU engines with high specific fuel consumption (0.69 kg/(kgf·h).

The medium-range Tu-204, which replaced the Tu-154 with 4th generation PS-90 engines, in the conditions of the collapse of the country and the free market, could not withstand competition with foreign manufacturers even in the struggle for domestic air carriers. Meanwhile, the segment of medium-haul narrow-body aircraft, dominated by the Boeing 737 and Airbus 320 (in 2015 alone, 986 of them were delivered to airlines around the world), is the most widespread, and presence in it is a necessary condition for preserving the domestic civil aircraft industry. Thus, in the early 2000s, an urgent need was identified to create a competitive new generation turbojet engine for a medium-range aircraft with 130-170 seats. Such an aircraft should be the MS-21 (Mainline Aircraft of the 21st Century), developed by the United Aircraft Corporation. The task is incredibly difficult, since not only the Tu-204, but also no other aircraft in the world could withstand the competition with Boeing and Airbus. It is for MS-21 that the PD-14 is being developed. Success in this project will be akin to an economic miracle, but such undertakings are the only way for the Russian economy to get off the oil needle.

PD-14 - basic design for the engine family

The letters “PD” stand for advanced engine, and the number 14 stands for thrust in ton-force. PD-14 is the base engine for the family of turbojet engines with a thrust from 8 to 18 tf. The business idea of the project is that all these engines are created on the basis of a unified gas generator of a high degree of perfection. The gas generator is the heart of the turbojet engine, which consists of a high-pressure compressor, combustion chamber and turbine. It is the manufacturing technologies of these components, primarily the so-called hot part, that are critical.

The family of engines based on the PD-14 will make it possible to equip almost all Russian aircraft with modern power plants: from the PD-7 for the short-haul Sukhoi Superjet 100 to the PD-18, which can be installed on the flagship of the Russian aircraft industry - the long-haul Il-96. Based on the PD-14 gas generator, it is planned to develop a PD-10V helicopter engine to replace the Ukrainian D-136 on the world's largest Mi-26 helicopter. The same engine can also be used on the Russian-Chinese heavy helicopter, the development of which has already begun. On the basis of the PD-14 gas generator, gas pumping installations and gas turbine power plants with a capacity of 8 to 16 MW, which are so necessary for Russia, can be created.

PD-14 is 16 critical technologies

For the PD-14, with the leading role of the Central Institute of Aviation Engine Manufacturing (CIAM), the leading research institute of the industry and the Aviadvigatel Design Bureau, 16 critical technologies were developed: monocrystalline high-pressure turbine blades with a promising cooling system, operable at gas temperatures up to 2000 °K, hollow wide-chord fan blade made of titanium alloy, thanks to which it was possible to increase the efficiency of the fan stage by 5% in comparison with PS-90, low-emission combustion chamber made of intermetallic alloy, sound-absorbing structures made of composite materials, ceramic coatings on the hot part parts, hollow low-pressure turbine blades and etc.

PD-14 will continue to be improved. At MAKS 2015, one could already see the prototype of a wide-chord fan blade made of carbon fiber, created at CIAM, the mass of which is 65% of the mass of the hollow titanium blade currently used. At the CIAM stand, one could also see a prototype of the gearbox that is supposed to be equipped with the modification of the PD-18R. The gearbox will allow you to reduce the fan speed, due to which, not tied to the turbine speed, it will operate in a more efficient mode. It is expected to raise the gas temperature in front of the turbine by 50 °K. This will increase the thrust of the PD-18R to 20 tf, and reduce specific fuel consumption by another 5%.

PD-14 is 20 new materials

When creating the PD-14, the developers from the very beginning relied on domestic materials. It was clear that under no circumstances would Russian companies be given access to new foreign-made materials. Here, the All-Russian Institute of Aviation Materials (VIAM) played a leading role, with the participation of which about 20 new materials were developed for the PD-14.

But creating the material is half the battle. Sometimes Russian metals are superior in quality to foreign ones, but their use in a civil aircraft engine requires certification according to international standards. Otherwise, the engine, no matter how good it is, will not be allowed to fly outside Russia. The rules here are very strict because we are talking about people's safety. The same applies to the engine manufacturing process: enterprises in the industry require certification according to the standards of the European Aviation Safety Agency (EASA). All this will force us to improve production standards, and it is necessary to re-equip the industry to accommodate new technologies. The development of the PD-14 itself took place using new, digital technology, thanks to which the 7th copy of the engine was assembled in Perm using mass production technology, while previously a pilot batch was produced in quantities of up to 35 copies.

PD-14 should take the entire industry to a new level. What can I say, even the Il-76LL flying laboratory, after several years of inactivity, needed to be retrofitted with equipment. Work has also been found for the unique CIAM stands, which allow simulating flight conditions on the ground. In general, the PD-14 project will save more than 10,000 highly qualified jobs for Russia.

PD-14 is the first domestic engine that directly competes with its Western counterpart

The development of a modern engine takes 1.5-2 times longer than the development of an aircraft. Unfortunately, aircraft manufacturers are faced with a situation where the engine does not have time to start testing the aircraft for which it is intended. The rollout of the first copy of the MS-21 will take place at the beginning of 2016, and testing of the PD-14 has just begun. True, the project provided an alternative from the very beginning: MS-21 customers could choose between the PD-14 and Pratt & Whitney’s PW1400G. It is with the American engine that the MC-21 will go on its first flight, and it is with it that the PD-14 will have to compete for a place under the wing.

Compared to its competitor, the PD-14 is somewhat inferior in efficiency, but it is lighter, has a noticeably smaller diameter (1.9 m versus 2.1), and therefore less resistance. And one more feature: Russian specialists deliberately went for some simplification of the design. The basic PD-14 does not use a gearbox in the fan drive, and also does not use an adjustable nozzle of the external circuit; it has a lower gas temperature in front of the turbine, which makes it easier to achieve reliability and service life indicators. Therefore, the PD-14 engine is cheaper and, according to preliminary estimates, will require lower maintenance and repair costs. By the way, in the context of falling oil prices, it is lower operating costs, and not efficiency, that become the driving factor and the main competitive advantage of an aircraft engine. In general, the direct operating costs of the MS-21 with the PD-14 can be 2.5% lower than that of the version with the American engine.

To date, 175 MS-21 have been ordered, of which 35 are with the PD-14 engine

The development and production of aircraft turbojet engines today is one of the most knowledge-intensive and scientifically and technically advanced industrial sectors. Apart from Russia, only the USA, England and France have a full cycle of creation and production of aviation gas turbine engines.

At the end of the last century, a number of factors came to the fore that had a strong impact on the prospects for the global aircraft engine industry - rising costs, increasing the overall development time and price of aircraft engines. The growth in cost indicators of aircraft engines is becoming exponential, while from generation to generation the share of exploratory research to create an advanced scientific and technical reserve becomes larger. For the US aircraft engine industry, during the transition from the fourth to the fifth generation, this share increased in cost from 15% to 60%, and in terms of time almost doubled. The situation in Russia was aggravated by well-known political events and a systemic crisis at the beginning of the 21st century.

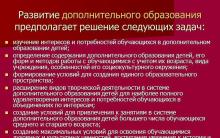

The United States, on a state budget basis, is today implementing a national program of key technologies for aircraft engine construction, INRTET. The ultimate goal is to achieve a monopoly position by 2015, pushing everyone else out of the market. What is Russia doing today to prevent this?

The head of CIAM, V. Skibin, said at the end of last year: “We have little time, but a lot of work.” However, the research carried out by the parent institute does not find a place in long-term plans. When creating the Federal Target Program for the Development of Civil Aviation Equipment until 2020, CIAM’s opinion was not even asked. “In the draft Federal Target Program we saw very serious issues, starting with the setting of tasks. We see unprofessionalism. In the draft Federal Target Program 2020, it is planned to allocate only 12% to science, 20% to engine building. This is not enough at all. The institutions were not even invited to discuss the draft Federal Target Program,” emphasized V. Skibin.

Andrey Reus. Yuri Eliseev. Vyacheslav Boguslaev.

CHANGE OF PRIORITIES

Federal program “Development of civil aviation equipment in Russia for 2002-2010.” and for the period until 2015." the creation of a number of new engines was envisaged. CIAM, based on the forecast for the development of the aviation market, has developed technical specifications for the competitive development of technical proposals for the creation of new generation engines provided for by the specified Federal Target Program: turbofan engines with a thrust of 9000-14000 kgf for short-medium-haul aircraft, turbofan engines with a thrust of 5000-7000 kgf for a regional aircraft, a gas turbine engine with a power 800 hp for helicopters and light aircraft, gas turbine engine with a power of 500 hp. for helicopters and light aircraft, aircraft piston engine (APE) with a power of 260-320 hp. for helicopters and light aircraft and APD with a power of 60-90 hp. for ultra-light helicopters and airplanes.

At the same time, a decision was made to reorganize the industry. The implementation of the federal program “Reform and development of the military-industrial complex (2002-2006)” provided for work to be carried out in two stages. At the first stage (2002-2004), it was planned to implement a set of measures to reform system-forming integrated structures. At the same time, it was planned to create nineteen integrated structures in the aviation industry, including a number of structures for engine-building organizations: OJSC Corporation Complex named after N.D. Kuznetsov”, OJSC “Perm Engine Building Center”, FSUE “Salyut”, OJSC “Air Screws Corporation”.

By this time, domestic engine engineers had already realized that it was pointless to hope for cooperation with foreign enterprises, and it was very difficult to survive alone, and they began to actively put together their own coalitions, which would allow them to take their rightful place in the future integrated structure. Aviation engine manufacturing in Russia has traditionally been represented by several “bushes”. Design bureaus were at the head, serial enterprises were at the next level, and aggregators were behind them. With the transition to a market economy, the leading role began to shift to serial factories that received real money from export contracts - MMPP "Salut", MMP named after. Chernysheva, UMPO, Motor Sich.

By this time, domestic engine engineers had already realized that it was pointless to hope for cooperation with foreign enterprises, and it was very difficult to survive alone, and they began to actively put together their own coalitions, which would allow them to take their rightful place in the future integrated structure. Aviation engine manufacturing in Russia has traditionally been represented by several “bushes”. Design bureaus were at the head, serial enterprises were at the next level, and aggregators were behind them. With the transition to a market economy, the leading role began to shift to serial factories that received real money from export contracts - MMPP "Salut", MMP named after. Chernysheva, UMPO, Motor Sich.

MMPP "Salyut" in 2007 turned into an integrated structure of the Federal State Unitary Enterprise "Research and Production Center for Gas Turbine Construction" Salyut ". It included branches in Moscow, the Moscow region and Bendery. Controlling and blocking stakes in joint stock companies NPP Temp, KB Elektropribor, NIIT, GMZ Agat and JV Topaz were managed by Salyut. A huge advantage was the creation of our own design bureau. This design bureau quickly proved that it was capable of solving serious problems. First of all, the creation of modernized AL-31FM engines and the development of a promising engine for fifth-generation aircraft. Thanks to export orders, Salyut carried out a large-scale modernization of production and carried out a number of R&D projects.

The second center of attraction was NPO Saturn, essentially the first vertically integrated company in Russia in the field of aircraft engine building, which united a design bureau in Moscow and a serial plant in Rybinsk. But unlike Salyut, this association was not supported by the necessary financial resources of its own. Therefore, in the second half of 2007, Saturn began a rapprochement with UMPO, which had a sufficient number of export orders. Soon, reports appeared in the press that the management of Saturn had become the owner of a controlling stake in UMPO, and a complete merger of the two companies was expected.

With the arrival of new management, Klimov OJSC became another center of attraction. Essentially, this is a design bureau. The traditional serial plants producing the products of this design bureau are the Moscow MPP named after. Chernyshev and Zaporozhye Motor Sich. The Moscow enterprise had fairly large export orders for RD-93 and RD-33MK engines; the Cossacks remained practically the only enterprise supplying TV3-117 engines for Russian helicopters.

Salyut and Saturn (if we count them together with UMPO) mass-produced AL-31F engines, one of the main sources of export income. Both enterprises had civilian products - SaM-146 and D-436, but both of these engines are of non-Russian origin. Saturn also produces engines for unmanned aerial vehicles. Salyut has such an engine, but there are no orders for it yet.

Klimov has no competitors in Russia in the field of engines for light fighters and helicopters, but everyone competed in the field of creating engines for training aircraft. MMPP named after. Chernyshev, together with TMKB Soyuz, created the RD-1700 turbofan engine, Saturn, commissioned by India, created the AL-55I, Salyut, in cooperation with Motor Sich, produced the AI-222-25. In reality, only the latter is installed on production aircraft. In the field of re-motorization, the Il-76 Saturn competed with the Perm PS-90, which remains the only engine installed on Russian long-haul aircraft today. However, the Perm “bush” had no luck with shareholders: the once powerful enterprise changed hands, and its power was wasted in the leapfrog of changes of non-core owners. The process of creating a Perm engine-building center dragged on; the most talented specialists moved to Rybinsk. Currently, the United Engine Corporation (UEC) is closely involved in optimizing the management structure of the Perm “bush.” A number of technologically related enterprises, which were separated from it in the past, are currently being integrated into the PMZ. A project to create a unified structure with the participation of PMZ and Aviadvigatel Design Bureau is being discussed with American partners from Pratt & Whitney. At the same time, before the beginning of April of this year, UEC will eliminate the “extra link” in the management of its Perm assets - the Perm representative office of the corporation, which has become the legal successor of CJSC Management Company Perm Engine-Building Complex (MC PMK), which from 2003 to 2008. managed the enterprises of the former Perm Motors holding company.

AI-222-25.

The most problematic issues remained the creation of an engine in the 12000-14000 kgf thrust class for a promising short-medium-haul airliner, which should replace the Tu-154. The main struggle took place between the Perm engine builders and the Ukrainian Progress. The Permians proposed to create a new generation PS-12 engine, their competitors proposed the D-436-12 project. The lower technical risk when creating the D-436-12 was more than offset by political risks. The seditious thought crept in that an independent breakthrough in the civilian segment had become unlikely. The civil jet engine market today is even more tightly divided than the aircraft market. Two American and two European companies are covering all possible niches, actively cooperating with each other.

Several Russian engine manufacturing enterprises remained on the sidelines of the struggle. New developments by AMNTK Soyuz turned out to be unnecessary; Samara enterprises had no competitors in the domestic market, but there was practically no market for them. Samara aircraft engines power strategic aircraft, of which not many were built in Soviet times. In the early 1990s, the promising NK-93 TVVD was developed, but it was not in demand in the new conditions.

Today, according to Andrey Reus, General Director of OJSC OPK Oboronprom, the situation in Samara has changed dramatically. The Samara "bush" plan for 2009 was fully implemented. In 2010, it is planned to complete the merger of the three enterprises into a single NPO, and to sell the excess space. According to A. Reus, “the crisis situation for Samara is over, normal work has begun. Productivity levels remain lower than the industry as a whole, but positive changes in production and financial areas are evident. In 2010, UEC plans to bring Samara enterprises to break-even operation.”

There still remains the problem of small and sport aviation. Oddly enough, they also need engines. Today, from domestic engines, you can choose only one - the piston M-14 and its derivatives. These engines are produced in Voronezh.

In August 2007, at a meeting in St. Petersburg on the development of engine manufacturing, then Russian President Vladimir Putin gave instructions to create four holding companies, which would then merge into one company. At the same time, V. Putin signed a Decree on the merger of Salyut with the Federal State Unitary Enterprise Omsk Engine-Building Association named after P.I. Baranov." The deadline for the Omsk plant to join Salyut changed periodically. In 2009, this did not happen because the Omsk plant had significant debt obligations, and Salyut insisted that the debt be repaid. And the state paid it off, allocating 568 million rubles in December last year. According to the leadership of the Omsk region, there are now no obstacles to unification, and this will happen in the first half of 2010.

Of the three remaining holdings, after several months it was considered advisable to create one association. In October 2008, Russian Prime Minister Vladimir Putin instructed to transfer state stakes in ten enterprises to Oboronprom and to ensure a controlling stake in the newly created UEC in a number of enterprises, including Aviadvigatel, NPO Saturn, and Perm Motors. , PMZ, UMPO, Motorostroitele, SNTK im. Kuznetsov and a number of others. These assets came under the control of Oboronprom's subsidiary, the United Engine Corporation. Andrey Reus argued this decision as follows: “if we had followed the path of the intermediate stage of creating several holdings, we would never have agreed to make one product. Four holdings are four model series that could never be brought to a single denominator. I'm not even talking about government assistance! One can only imagine what would happen in the struggle for budget funds. The same project to create an engine for the MS-21 involved NPP Motor, KB Aviadvigatel, Ufa Engine Production Association, Perm Motor Plant, and Samara “bush”. NPO Saturn, while there was no merger, refused to work on the project, but now it is an active participant in the process.”

AL-31FP.

Today, the strategic goal of UEC is “to restore and support the modern Russian engineering school in the field of creating gas turbine engines.” By 2020, UEC should gain a foothold in the top five global manufacturers in the field of gas turbine engines. By this time, 40% of sales of UEC products should be targeted at the world market. At the same time, it is necessary to ensure a fourfold, and possibly fivefold increase in labor productivity and the mandatory inclusion of service in the engine sales system. UEC's priority projects are the creation of the SaM-146 engine for the Russian regional aircraft SuperJet100, a new engine for civil aviation, an engine for military aviation, and an engine for a promising high-speed helicopter.

FIFTH GENERATION ENGINE FOR COMBAT AVIATION

The program for creating the PAK FA in 2004 was divided into two stages. The first stage involves the installation of a “117C” engine on the aircraft (today it is classified as generation 4+), the second stage involved the creation of a new engine with a thrust of 15-15.5 tons. The preliminary design of the PAK FA still includes the Saturn engine.

The competition announced by the Russian Ministry of Defense also included two stages: November 2008 and May-June 2009. Saturn was almost a year behind Salyut in providing the results of work on engine elements. Salyut did everything on time and received the commission’s conclusion.

Apparently, this situation prompted UEC in January 2010 to finally propose to Salyut to create a fifth-generation engine jointly. A preliminary agreement was reached to divide the workload approximately fifty-fifty. Yuri Eliseev agrees to work with UEC on a parity basis, but believes that Salyut should be the ideologist of the creation of a new engine.

MMPP "Salyut" has already created the AL-31FM1 engines (it has been put into service and is being mass-produced) and AL-31FM2, and has moved on to bench development of the AL-31FM3-1, which will be followed by the AL-31FM3-2. Each new engine is characterized by increased traction and better resource indicators. AL-31FM3-1 received a new three-stage fan and a new combustion chamber, and the thrust reached 14,500 kgf. The next step involves increasing thrust to 15,200 kgf.

According to Andrei Reus, “the PAK FA topic leads to very close cooperation, which can be considered as a basis for integration.” At the same time, he does not exclude that in the future a unified structure in engine building will be created.

The SaM-146 program is an example of successful cooperation in the field of high technology between the Russian Federation and France.

Several years ago, Aviadvigatel OJSC (PD-14, formerly known as PS-14) and Salyut together with the Ukrainian Motor Sich and Progress (SPM-21) presented their proposals for a new engine for the MS-21 aircraft. . The first was a completely new work, and the second was planned to be created on the basis of the D-436, which would significantly reduce the time frame and reduce technical risks.

At the beginning of last year, UAC and NPK Irkut finally announced a tender for engines for the MS-21 aircraft, issuing technical specifications to several foreign engine-building companies (Pratt & Whitney, CFM International) and the Ukrainian Motor Sich and Ivchenko-Progress. in cooperation with the Russian Salyut. The creator of the Russian version of the engine has already been determined - UEC.

The family of engines under development includes several heavy engines with greater thrust than is necessary for the MC-21. There is no direct funding for such products, but in the future high-thrust engines will be in demand, including to replace the PS-90A on currently flying aircraft. All higher thrust engines are planned to be geared.

An engine with a thrust of 18,000 kgf may also be required for a promising light wide-body aircraft (LSA). Engines with such thrust are also necessary for the MC-21-400.

In the meantime, NPK Irkut has decided to equip the first MS-21 with PW1000G engines. The Americans promise to have this engine ready by 2013, and apparently Irkut already has reason not to be afraid of the US State Department’s bans and the fact that there may simply not be enough such engines for everyone if a decision is made to remotorize Boeing 737 and Airbus A320 aircraft.

In early March, PD-14 passed the “second gate” at a meeting at the UEC. This means established cooperation for the production of a gas generator, proposals for cooperation in the production of an engine, as well as a detailed market analysis. PMZ will manufacture the combustion chamber and high-pressure turbine. A significant part of the high-pressure compressor, as well as the low-pressure compressor, will be produced by UMPO. For the low-pressure turbine, cooperation with Saturn is possible, and cooperation with Salyut is not excluded. The engine will be assembled in Perm.

The preliminary design of the PAK FA still includes the Saturn engine.

OPEN ROTOR ENGINES

Despite the fact that Russian aircraft pilots do not yet recognize the open rotor, engine experts are confident that it has advantages and “aircraft will mature to this engine.” Therefore, today Perm is carrying out relevant work. The Cossacks already have serious experience in this area, associated with the D-27 engine, and in the family of open-rotor engines, the development of this unit will probably be given to the Cossacks.

Before MAKS-2009, work on the D-27 at the Moscow Salyut was frozen: there was no funding. On August 18, 2009, the Russian Ministry of Defense signed a protocol on amending the agreement between the governments of Russia and Ukraine on the An-70 aircraft, Salyut began active work on the manufacture of parts and components. Today there is an additional agreement for the supply of three sets and components for the D-27 engine. The work is financed by the Russian Ministry of Defense; the units built by Salyut will be transferred to the Ivchenko-Progress State Enterprise to complete state tests of the engine. General coordination of work on this topic has been entrusted to the Ministry of Industry and Trade of the Russian Federation.

There was also the idea of using D-27 engines on Tu-95MS and Tu-142 bombers, but Tupolev OJSC is not yet considering such options; the possibility of installing D-27 on the A-42E aircraft was studied, but then it was replaced by the PS-90.

At the beginning of last year, UAC and NPK Irkut announced a tender for engines for the MS-21 aircraft.

HELICOPTER ENGINES

Today, most Russian helicopters are equipped with Zaporozhye-made engines, and for those engines that Klimov assembles, gas generators are still supplied by Motor Sich. This enterprise now significantly exceeds Klimov in the number of helicopter engines produced: the Ukrainian company, according to available data, supplied 400 engines to Russia in 2008, while Klimov OJSC produced about 100 units.

Klimov and MMP im. V.V. Chernysheva. It was planned to move the production of TV3-117 engines to Russia, building a new plant and taking away the main source of income from Motor Sich. At the same time, Klimov was one of the active lobbyists for the import substitution program. In 2007, the final assembly of the VK-2500 and TV3-117 engines was supposed to be concentrated at the MMP named after. V.V. Chernysheva.

Today, UEC plans to entrust the production, overhaul and after-sales service of TV3-117 and VK-2500 helicopter engines to UMPO. Also in Ufa they expect to launch the Klimovsky VK-800V into series. 90% of the financial resources required for this are expected to be attracted through the federal target programs “Development of Civil Aviation Equipment”, “Import Substitution” and “Development of the Military-Industrial Complex”.

D-27 engines.

The production of gas generators to replace the Ukrainian ones should be established at UMPO from 2013. Until this time, gas generators will continue to be purchased from Motor Sich. UEC plans to use the capacity of JSC Klimov “to the maximum” until 2013. What Klimov cannot do will be ordered from Motor Sich. But already in 2010-2011. it is planned to minimize purchases of repair kits at Motor Sich. Starting in 2013, when engine production at Klimov will be phased out, the St. Petersburg enterprise will begin restructuring its premises.

As a result, Klimov received the status of the leading developer of helicopter engines and turbojet engines in the afterburning thrust class up to 10 tf in the UEC. The priority areas today are carrying out R&D work on the TV7-117V engine for the Mi-38 helicopter, modernizing the VK-2500 engine in the interests of the Russian Defense Ministry, and completing R&D work on the RD-33MK. The company is also taking part in the development of the fifth generation engine under the PAK FA program.

At the end of December 2009, the UEC project committee approved the Klimova project for the construction of a new design and production complex with the release of sites in the center of St. Petersburg.

MMP im. V.V. Chernysheva will now carry out serial production of a single helicopter engine - TV7-117V. This engine was created on the basis of the TV7-117ST aircraft turboprop engine for the Il-112V aircraft, and its production is also already being mastered by this Moscow enterprise.

In response, Motor Sich in October last year proposed that UEC create a joint management company. “The management company can be a transitional option for further integration,” explained Vyacheslav Boguslaev, Chairman of the Board of Directors of Motor Sich OJSC. According to Boguslaev, UEC could well acquire up to 11% of Motor Sich shares, which are in free circulation on the market. In March 2010, Motor Sich took another step, inviting the Kazan Engine Production Association to open the production of engines for the Ansat light multi-purpose helicopter using its vacated facilities. MS-500 is an analogue of the PW207K engine, which is currently equipped with Ansat helicopters. According to the terms of contracts of the Russian Ministry of Defense, Russian equipment must be equipped with domestic components, and an exception for Ansat was made because there is no real replacement for Canadians yet. This niche could be filled by KMPO with the MS-500 engine, but for now the issue comes down to cost. The MS-500 price is about $400 thousand, and the PW207K costs $288 thousand. However, in early March the parties signed a software contract with the intention of concluding a licensing agreement (50:50). KMPO, which several years ago invested heavily in the creation of a Ukrainian engine

AI-222 for the Tu-324 aircraft, in this case wants to protect itself with a licensing agreement and receive a guarantee of return on investment.

However, the Russian Helicopters holding company sees the Klimovsky VK-800 engine as the Ansat power plant, and the option with the MS-500V engine is “being considered among others.” From the point of view of the military, both Canadian and Ukrainian engines are equally foreign.

In general, today UEC does not intend to take any steps to merge with Zaporozhye enterprises. Motor Sich has made a number of proposals for joint production of engines, but they run counter to UEC’s own plans. Therefore, “the correctly structured contractual relationship with Motor Sich today suits us quite well,” noted Andrey Reus.

PS-90A2.

In 2009, PMZ built 25 new PS-90 engines, the rate of serial production remained at the level of 2008. According to the managing director of Perm Motor Plant OJSC, Mikhail Dicheskul, “the plant fulfilled all contractual obligations, not a single order was disrupted.” In 2010, PMZ plans to begin production of PS-90A2 engines, which were flight tested on a Tu-204 aircraft in Ulyanovsk and received a type certificate at the end of last year. This year it is planned to build six such engines.

D-436-148

D-436-148 engines for An-148 aircraft are supplied today by Motor Sich together with Salyut. The program of the Kyiv aircraft plant "Aviant" for 2010 includes the production of four An-148, the Voronezh aircraft plant - 9-10 aircraft. To do this, it is necessary to supply about 30 engines, including one or two reserve ones in Russia and Ukraine.

D-436-148.

SAM-146

More than 6,200 hours of testing have been carried out on the SaM-146 engine, of which over 2,700 hours were in flight. Under its certification program, over 93% of the planned tests have been completed. It is necessary to additionally test the engine for casting an average flock of birds, for fan blade breakage, check initial maintenance, pipelines, oil filter clogging sensors, pipelines in salt fog conditions.

SaM-146.

Obtaining European certification (EASA) for the standard engine design is scheduled for May. After this, the engine will have to receive validation from the Aviation Registry of the Interstate Aviation Committee.

Managing Director of Saturn Ilya Fedorov in March of this year once again stated that “there are no technical problems for the serial assembly of the SaM146 engine and its commissioning.”

The equipment in Rybinsk allows the production of up to 48 engines per year, and in three years their production can be increased to 150. The first commercial delivery of engines is planned for June 2010. Then - two engines every month.

Currently, Motor Sich manufactures D-18T series 3 engines and is working on the D-18T series 4 engine, but the company is trying to create a modernized D-18T series 4 engine in stages. The situation with the development of the D-18T series 4 is aggravated by the uncertainty of the fate of the modernized An-124-300 aircraft.

AI-222-25 engines for Yak-130 aircraft are produced by Salyut and Motor Sich. At the same time, there was practically no funding for the Russian part of the work on this engine last year - Salyut did not receive money for six months. As part of the cooperation, it was necessary to switch to barter: exchange D-436 modules for AI-222 modules and “save the An-148 and Yak-130 aircraft programs.”

The afterburning version of the AI-222-25F engine is already being tested; state tests are planned to begin at the end of 2010 or early 2011. A tripartite agreement has been signed between ZMKB Progress, JSC Motor Sich and FSUE MMPP Salyut for the promotion of this engine to the world market with the participation of each party.

Last year, the process of forming the final structure of the UEC was almost completed. In 2009, the total revenue of UEC enterprises amounted to 72 billion rubles. (in 2008 – 59 billion rubles). A significant amount of state support has allowed most enterprises to significantly reduce accounts payable, as well as ensure settlements with component suppliers.

Today there are three real players left in the Russian aviation engine manufacturing field - ODK, Salyut and Motor Sich. Time will tell how the situation will develop further.

Ctrl Enter

Noticed osh Y bku Select text and click Ctrl+Enter

Experimental samples of gas turbine engines (GTE) first appeared on the eve of World War II. The developments came to life in the early fifties: gas turbine engines were actively used in military and civil aircraft construction. At the third stage of introduction into industry, small gas turbine engines, represented by microturbine power plants, began to be widely used in all areas of industry.

General information about gas turbine engines

The operating principle is common to all gas turbine engines and consists in transforming the energy of compressed heated air into mechanical work of the gas turbine shaft. The air entering the guide vane and compressor is compressed and in this form enters the combustion chamber, where fuel is injected and the working mixture is ignited. Gases resulting from combustion pass through the turbine under high pressure and rotate its blades. Part of the rotational energy is spent on rotating the compressor shaft, but most of the energy of the compressed gas is converted into useful mechanical work of rotating the turbine shaft. Among all internal combustion engines (ICE), gas turbine units have the greatest power: up to 6 kW/kg.

Gas turbine engines operate on most types of dispersed fuel, which makes them stand out from other internal combustion engines.

Problems of developing small TGDs

As the size of the gas turbine engine decreases, the efficiency and specific power decrease compared to conventional turbojet engines. At the same time, the specific fuel consumption also increases; the aerodynamic characteristics of the flow sections of the turbine and compressor deteriorate, and the efficiency of these elements decreases. In the combustion chamber, as a result of a decrease in air flow, the combustion efficiency of the fuel assembly decreases.

A decrease in the efficiency of gas turbine engine components with a decrease in its dimensions leads to a decrease in the efficiency of the entire unit. Therefore, when modernizing the model, designers pay special attention to increasing the efficiency of individual elements, up to 1%.

For comparison: when the compressor efficiency increases from 85% to 86%, the turbine efficiency increases from 80% to 81%, and the overall engine efficiency increases by 1.7%. This suggests that for a fixed fuel consumption, the specific power will increase by the same amount.

Aviation gas turbine engine "Klimov GTD-350" for the Mi-2 helicopter

The development of the GTD-350 first began in 1959 at OKB-117 under the leadership of designer S.P. Izotov. Initially, the task was to develop a small engine for the MI-2 helicopter.

At the design stage, experimental installations were used, and the node-by-unit finishing method was used. In the process of research, methods for calculating small-sized bladed devices were created, and constructive measures were taken to dampen high-speed rotors. The first samples of a working model of the engine appeared in 1961. Air tests of the Mi-2 helicopter with GTD-350 were first carried out on September 22, 1961. According to the test results, two helicopter engines were torn apart, re-equipping the transmission.

The engine passed state certification in 1963. Serial production opened in the Polish city of Rzeszow in 1964 under the leadership of Soviet specialists and continued until 1990.

Ma l The second domestically produced gas turbine engine GTD-350 has the following performance characteristics:

— weight: 139 kg;

— dimensions: 1385 x 626 x 760 mm;

— rated power on the free turbine shaft: 400 hp (295 kW);

— free turbine rotation speed: 24000;

— operating temperature range -60…+60 ºC;

— specific fuel consumption 0.5 kg/kW hour;

— fuel — kerosene;

— cruising power: 265 hp;

— takeoff power: 400 hp.

For flight safety reasons, the Mi-2 helicopter is equipped with 2 engines. The twin installation allows the aircraft to safely complete the flight in the event of failure of one of the power plants.

The GTE-350 is currently obsolete; modern small aircraft require more powerful, reliable and cheaper gas turbine engines. At the present time, a new and promising domestic engine is the MD-120, produced by the Salyut corporation. Engine weight - 35 kg, engine thrust 120 kgf.

General scheme

The design of the GTD-350 is somewhat unusual due to the location of the combustion chamber not immediately behind the compressor, as in standard models, but behind the turbine. In this case, the turbine is attached to the compressor. This unusual arrangement of components reduces the length of the engine power shafts, therefore reducing the weight of the unit and allowing for high rotor speeds and efficiency.

During engine operation, air enters through the VNA, passes through the axial compressor stages, the centrifugal stage and reaches the air collecting scroll. From there, through two pipes, air is supplied to the rear of the engine to the combustion chamber, where it reverses the direction of flow and enters the turbine wheels. The main components of the GTD-350 are: compressor, combustion chamber, turbine, gas collector and gearbox. Engine systems are presented: lubrication, control and anti-icing.

The unit is divided into independent units, which makes it possible to produce individual spare parts and ensure their quick repair. The engine is constantly being improved and today its modification and production is carried out by Klimov OJSC. The initial resource of the GTD-350 was only 200 hours, but during the modification process it was gradually increased to 1000 hours. The picture shows the general mechanical connection of all components and assemblies.

Small gas turbine engines: areas of application

Microturbines are used in industry and everyday life as autonomous sources of electricity.

— The power of microturbines is 30-1000 kW;

— volume does not exceed 4 cubic meters.

Among the advantages of small gas turbine engines are:

— wide range of loads;

— low vibration and noise level;

— work on various types of fuel;

- small dimensions;

— low level of exhaust emissions.

Negative points:

— complexity of the electronic circuit (in the standard version, the power circuit is made with double energy conversion);

— a power turbine with a speed maintenance mechanism significantly increases the cost and complicates the production of the entire unit.

Today, turbogenerators have not become as widespread in Russia and the post-Soviet space as in the USA and Europe due to the high cost of production. However, according to calculations, a single autonomous gas turbine unit with a power of 100 kW and an efficiency of 30% can be used to supply energy to standard 80 apartments with gas stoves.

A short video of the use of a turboshaft engine for an electric generator.

By installing absorption refrigerators, a microturbine can be used as an air conditioning system and for simultaneous cooling of a significant number of rooms.

Automotive industry

Small gas turbine engines demonstrated satisfactory results during road tests, however, the cost of the vehicle increases many times due to the complexity of the design elements. Gas turbine engine with a power of 100-1200 hp. have characteristics similar to gasoline engines, but mass production of such cars is not expected in the near future. To solve these problems, it is necessary to improve and reduce the cost of all components of the engine.

Things are different in the defense industry. The military does not pay attention to cost; performance is more important to them. The military needed a powerful, compact, trouble-free power plant for tanks. And in the mid-60s of the 20th century, Sergei Izotov, the creator of the power plant for MI-2 - GTD-350, was involved in this problem. Izotov Design Bureau began development and eventually created the GTD-1000 for the T-80 tank. Perhaps this is the only positive experience of using gas turbine engines for ground transport. The disadvantages of using an engine on a tank are its gluttony and pickiness about the cleanliness of the air passing through the working path. Below is a short video of the operation of the tank GTD-1000.

Small aviation

Today, the high cost and low reliability of piston engines with a power of 50-150 kW do not allow Russian small aviation to confidently spread its wings. Engines such as Rotax are not certified in Russia, and Lycoming engines used in agricultural aviation are obviously overpriced. In addition, they run on gasoline, which is not produced in our country, which further increases the cost of operation.

It is small aviation, like no other industry, that needs small gas turbine engine projects. By developing the infrastructure for the production of small turbines, we can confidently talk about the revival of agricultural aviation. Abroad, a sufficient number of companies are engaged in the production of small gas turbine engines. Scope of application: private aircraft and drones. Among the models for light aircraft are the Czech engines TJ100A, TP100 and TP180, and the American TPR80.

In Russia, since the times of the USSR, small and medium-sized gas turbine engines have been developed mainly for helicopters and light aircraft. Their resource ranged from 4 to 8 thousand hours,

Today, for the needs of the MI-2 helicopter, small gas turbine engines of the Klimov plant continue to be produced, such as: GTD-350, RD-33, TVZ-117VMA, TV-2-117A, VK-2500PS-03 and TV-7-117V.

OJSC Kuznetsov is a leading engine-building enterprise in Russia. It carries out the design, manufacture and repair of rocket, aircraft and gas turbine units for the gas and energy industries.

These engines were used to launch the manned spacecraft Vostok, Voskhod, Soyuz and automatic transport cargo spacecraft Progress. 100% of manned space launches and up to 80% of commercial ones are carried out using RD107/108 engines and their modifications produced in Samara.

The plant's products are of particular importance for maintaining the combat readiness of Russian long-range aviation. At Kuznetsov, engines were designed, produced and technically maintained for the Tu-95MS long-range bombers, for the Tu-22M3 bombers and for the unique Tu-160.

1. 55 years ago, Samara began mass production of rocket engines, which were not only launched into orbit, but have been used by Russian cosmonautics and heavy aviation for more than half a century. The Kuznetsov enterprise, which is part of the Rostec State Corporation, united several large Samara factories. At first they were engaged in the production and maintenance of engines for launch vehicles of the Vostok and Voskhod rockets, now - for the Soyuz. The second direction of Kuznetsov’s work today is power plants for aircraft.

OJSC Kuznetsov is part of the United Engine Corporation (UEC).

2. . This is one of the initial stages of the engine manufacturing process. High-precision processing and testing equipment is concentrated here. For example, the DMU-160 FD milling processing center is capable of processing large-sized parts of complex shape with a diameter of up to 1.6 meters and a weight of up to 2 tons.

3. The equipment is operated in 3 shifts.

4. Processing on a rotary lathe.

5. NK-32 is installed on the Tu-160 strategic bomber, and NK-32-1 is installed on the Tu-144LL flying laboratory. The installation speed allows you to process seams up to 100 meters per minute.

6. . This site is capable of casting blanks with a diameter of up to 1,600 mm and a weight of up to 1,500 kg, required for housing parts of gas turbine engines for industrial and aviation applications. The photo shows the process of pouring a part in a vacuum melting furnace.

10. The test involves cooling a bath of alcohol using liquid nitrogen to a specified temperature.

20. Assembly of another prototype of the NK-361 engine for the Russian railway. A new direction of development of OJSC Kuznetsov is the production of mechanical drives of the GTE-8.3/NK power unit for the traction section of a main gas turbine locomotive based on the NK-361 gas turbine engine.

21. The first prototype of a gas turbine locomotive with an NK-361 engine in 2009, during tests on the experimental ring in Shcherbinka, carried a train weighing more than 15 thousand tons, consisting of 158 cars, thereby setting a world record.

24. - turbojet engine for the Tu-22M3 aircraft, the main Russian medium-range bomber. Along with the NK-32, it has long been one of the most powerful aircraft engines in the world.

Gas turbine engine NK-14ST used as part of a gas transportation unit. Interestingly, the engine uses natural gas pumped through pipelines as fuel. It is a modification of the NK-12 engine, which was installed on the Tu-95 strategic bomber.

29. Workshop for final assembly of serial rocket engines. The RD-107A/RD-108A engines developed by NPO Energomash OJSC are assembled here. These propulsion systems are equipped with the first and second stages of all Soyuz-type launch vehicles.

30. The enterprise’s share in the rocket engine segment on the Russian market is 80%, in manned launches - 100%. Engine reliability is 99.8%. Launches of launch vehicles with engines of JSC Kuznetsov are carried out from three cosmodromes - Baikonur (Kazakhstan), Plesetsk (Russia) and Kourou (French Guiana). The launch complex for Soyuz will also be built at the Russian Vostochny Cosmodrome (Amur Region).

33. Here, in the workshop, work is underway on the adaptation and assembly of the NK-33 rocket engine, intended for the first stage of the Soyuz-2-1v light-class launch vehicle.

34. - one of those that was planned to be destroyed after the closure of the lunar program. The engine is easy to operate and maintain, and at the same time has high reliability. Moreover, its cost is two times lower than the cost of existing engines of the same thrust class. NK-33 is in demand even abroad. Such engines are installed on the American Antares rocket.

36. In the final assembly shop of rocket engines there is a whole gallery with photographs of Soviet and Russian cosmonauts who went into space on rockets with Samara engines.

41. at the stand. A few minutes before the start of the fire tests.

There is only one way to confirm the almost one hundred percent reliability of a product: send the finished engine for testing. It is mounted on a special stand and launched. The propulsion system must operate as if it were already launching a spacecraft into orbit.

42. For more than half a century of work, Kuznetsov produced about 10 thousand liquid rocket engines of eight modifications, which launched into space more than 1,800 launch vehicles of the Vostok, Voskhod, Molniya and Soyuz types.

43. When ready for a minute, water is supplied to the torch cooling system, creating a water carpet that reduces the temperature of the torch and the noise from the running engine.

44. When testing an engine, about 250 parameters are recorded, by which the quality of the engine’s manufacturing is assessed.

47. Preparing the engine at the stand lasts several hours. It is connected with sensors, their functionality is checked, the lines are pressure tested, and the operation of the stand and engine automation is comprehensively checked.

48. Technological control tests last about a minute. During this time, 12 tons of kerosene and about 30 tons of liquid oxygen are burned.

49. The tests are over. After this, the engine is sent to the assembly shop, where it is disassembled, components are inspected, assembled, final inspection is carried out, and then sent to the customer - to JSC RCC Progress. There it is installed on the rocket stage.

"pros" and "cons" of democracy

Surveyor. Who is a surveyor? Description of the profession. Profession surveyor Surveyor training

Magellanic clouds: who are they?

Pepper Steak Sauce Creamy Pepper Sauce

How to create a competent portfolio for a designer